Home > SMT Assembly Line

Hanwha Decan S2 SMT Assembly line

Products description:

Hanwha Decan S2 SMT Assembly line

Automatic Hanwha SMT Assembly line, with Hanwha Decan S2, Decan L2, this SMT assembly line is suitable for home appliance industry: air conditioners, refrigerators, washing machines, water heaters, induction cookers, LED lamps, indoor lighting equipment, outdoor lighting equipment, industrial lighting

Hanwha Pick and place machine DECAN S2, DECAN S2 has better area capacity than competitors' similar equipment, optimized High-speed placement of small components; The DECAN S2 high-speed chip placement machine is equipped with 10 shafts per head and is suitable for dual cantilever, magnetically levitated high-performance placement machines, which can achieve the highest speed in the world's same-class products. 92,000CPH.

1. PCB loader

Micro computer controlled component ensures machine’s stable and reliable running.

Optional Fuji buttons interface or touch panel interface, convenient man-machine interaction.

Multiple sound and light alarming functions

Use standard magazines, good compatibility, load with 3 magazines at one time.

Lifting distance adjustable according to PCB, 4 kinds of distance(10mm, 20mm, 30mm and 40mm)

Loader configured with inner push board component, save the cost of buying PCB moving machine independently.

Automatic counting function make it easy of production statistic

Optional SMEMA port for communication between machines.

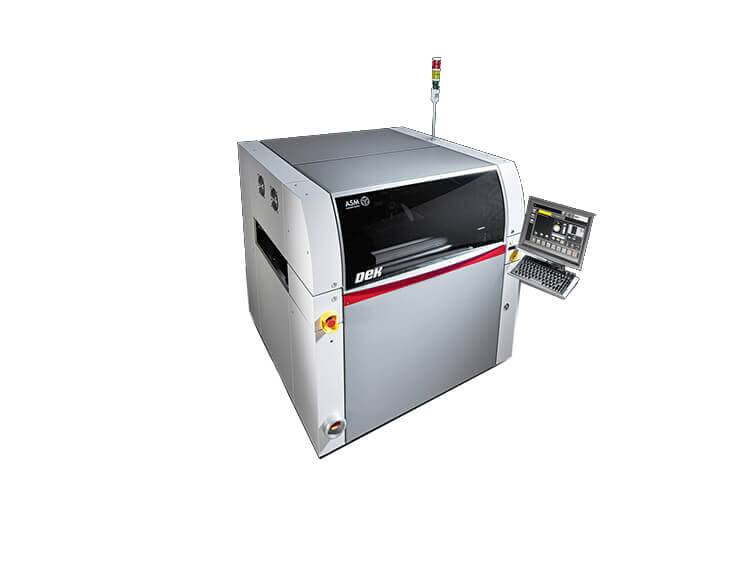

2. DEK Neo Horizon SMT Stencil Printer

With its modular design, the latest generation of our powerful screen printers is customizable for any customer-specific or application-specific requirements. Clamping systems, conveyors, tooling, paste management, verification – the DEK NeoHorizon can be equipped and/or retrofitted with many powerful and precision-enhancing options. All this flexibility can be controlled easily and comfortably with the leading printer software: DEK Instinctiv™ V9.

Two basic printer configurations are available: The DEK NeoHorizon 03 iX with the DEK HawkEye 750 camera system, semi-automatic stencil load and the IUSC understencil cleaning system features a core cycle time of 8.0 seconds and a machine accuracy of ±20 µm @ 2 Cmk for use in high-mix environments. The DEK NeoHorizon 01 iX with its core cycle time of 6,5 seconds and enhanced machine accuracy of ±15 µm @ 2 Cmk was designed for applications with particularly high demands on quality and throughput, for example for 0201 (metric) components. This configuration is equipped with the high-resolution DEK HawkEye 1700 camera, a fully automatic stencil alignment system, and the high-end DEK Cyclone understencil cleaning system.

3. Hanwha Decan S2 Pick and place machine.

1 Speed: 92000CPH

2 Accuracy: CHIP 28um (03015), IC 25um

3 Mountable components (mm): Chip 03015 ~ 5 axis: 12-h10 10 axis: 6-h10

Number of 4 shafts: 10 x 2 Head

5 Fly Camera FOV: 20.5mm

6 PCB size: 50 x 40 ~ 510 x 460mm

Max. 740 x 460 mm (1,200 x 460 mm)

7 material station: 120ea

8 Equipment weight: 1,800kg

9 Device size (mm): 1,430 (L) x 1,740 (D) x 1,485 (H)

10 Power: 3 phase AC 200/208/220/240/380 / 415V ± 10%;

50 / 60Hz; Max. 5.0 Kva

4. Hanwha DECAN L2 Pick and Place Machine

Speed : 56,000 CPH (Optimum)

Structure : 2 Gantry x 6 Spindles/Head

Accuracy : ±40μm Cpk≥1.0 (0402 Chip)

±30μm Cpk≥1.0 (IC)

Parts Size : 0402~□55mm, L75 (H25mm)

PCB Size : L510xW460mm (Standard)

L1,200xW460mm (Option)

Wide Part Handling Capability

Various PCB Transfer Systems

Verified Production History Management Solution

High Speed Placement

Dimension(mm):1,430(L) x 1,740(D) x 1,485(H)

Weight: 1,800kg

5. Heller 1936 MKV SMT Reflow Oven.

This new oven has been designed to meet Semi S2/S8 safety standards (including toxic gases).

Formic Acid has been shown to be an effective reducing agent in fluxless solder reflow

Excellent results demonstrated for wafer bumping application in horizontal reflow oven

Fluxless reflow utilizes gas phase Formic Acid (HCOOH) to replace standard fluxing agents

Eliminates the need for pre-reflow fluxing and post-reflow flux cleanup steps

No post-reflow flux clean facilitates inline application of epoxy and inline epoxy curing solution

Feasibility has been demonstrated with production grade oven

Extensive engineering efforts in safe, precision delivery of formic acid and abatement

6. Koh Young ZENITH Alpha 3D AOI

1: Advanced Hardware FeaturesThe World's Best-selling & First Full 3D Automated Optical Inspection Eliminates all the sources of defects using full 3D measuring inspection equipment skills- Removes shadow problems utilizing 8-way projection- Realizes perfect 3D solder joint inspection- Provides accurate inspection data with real-time PCB warp compensation· Full 3D data-based process optimization solution: Realization of industry 4.0 smart factory- Process information DB and real-time remote monitoring- Inspection program management automation & efficiency· Optimized specification model for a variety of production environment

High-precision weld seam measurement algorithm provided by KOH YOUNG technology for artificial intelligence

1.PLC+Touch screen control , easy to operate.

2.Design with firm structure.

3.The upper and lower air clamps ensure the location of the material box accurately.

4.Special gas path design ensures that the PCB panel is not pushed.

5.Automatic detection of fault code display function.

6.With SMEMA signal.

Keywords:

SMT Assembly line, PCB Assembly line, JUKI SMT Assembly Line, Samsung SMT Assembly Line, Hanwha SMT Assembly Line, Panasonic SMT Assembly Line, FUJI SMT Assembly Line, Yamaha SMT Assembly Line.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China